Visbreaking – Application Overview

Visbreaking is a mild form of thermal cracking. It significantly lowers the viscosity of heavy crude-oil residue without affecting the boiling point range. Residual from the atmospheric distillation tower is heated (400-500°C) at atmospheric pressure and mildly cracked in a heater. It is then quenched with cool gas oil to control over-cracking and flashed in a distillation tower.

Visbreaking is used to reduce the quantity of residual oil and to increase the yield of more valuable middle distillates like diesel and heavy oil. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons like LPG and petrol. The thermally cracked residue tar, which accumulates in the bottom of the fractionation column, is vacuum flashed in a stripper and the distillate recycled.

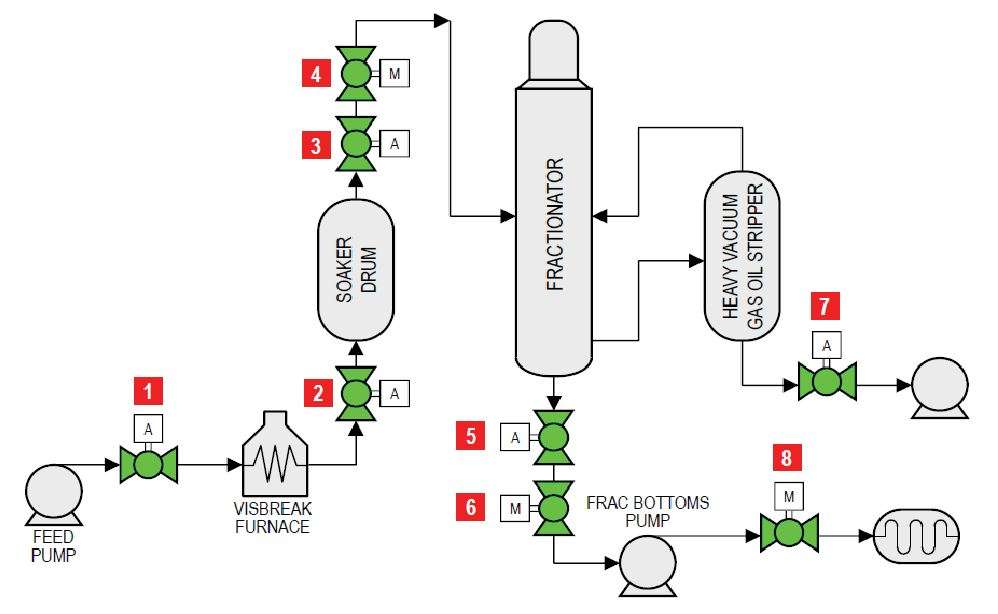

| FLOW DIAGRAM | |||||

|

|||||

| Item | Applications | Temp range (°F) | Pressure (psi) | Size (in) | |

| 1 | Feed isolation | 150 – 320 | 100 – 250 | 4 – 12 | |

| 2 | Visbreaker furnace isolation | 300 – 450 | 100 – 250 | 4 – 12 | |

| 3 | Automated soaker drum isolation | 300 – 450 | 100 – 250 | 4 – 12 | |

| 4 | Manual soaker drum isolation | 300 – 450 | 100 – 250 | 4 – 12 | |

| 5 | Frac bottoms tower emergency block valve | 300 – 450 | 30 – 75 | 4 – 12 | |

| 6 | Frac bottoms pump isolation | 300 – 450 | 30 – 75 | 4 – 12 | |

| 7 | Heavy vacuum gas oil stripper emergency block valve | 300 – 450 | 30 – 75 | 4 – 12 | |

| 8 | Frac tower bottom heat exchanger isolation | 300 – 450 | 30 – 75 | 4 – 12 | |